How To Prevent Steel Corrosion On Steel Products

How To Prevent Steel Corrosion On Steel Products

How To Prevent Steel Corrosion On Steel Products

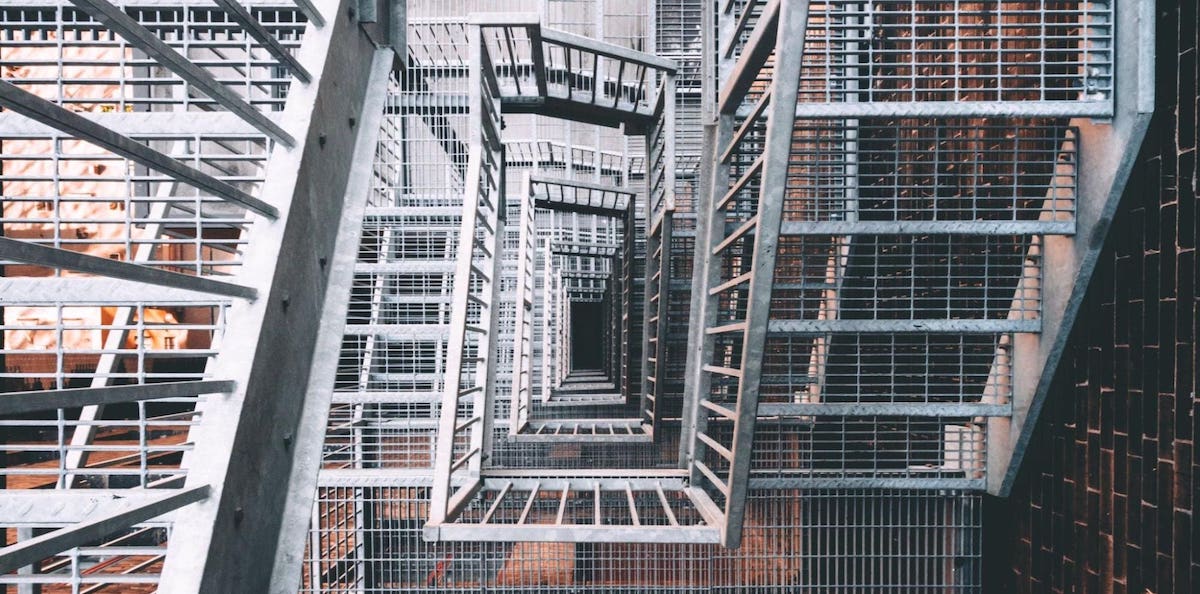

Whilst steel is an impressively strong product used across the construction industry for centuries, it’s in no way entirely impervious to damage over time. Once steel corrosion sets it, it can significantly impact the life and structural integrity of steel products, leading to potentially costly repairs and replacements – a nightmare for builders, project managers, and more.

As a leading supplier of steel products, Australian Steel Traders (AST) understands the importance of preventing corrosion to ensure the durability and reliability of steel items, particularly if they are central to the structure of a building or vehicle. We’ve found a number of effective ways to prevent steel corrosion that you can put into practice to ensure that your constructs remain safe and sound.

Apply Proper Coating And Painting

Applying suitable coatings and paints to steel products is one of the most common and effective ways to prevent corrosion. Coatings such as galvanising and zinc plating create a protective barrier that shields the steel from direct exposure to moisture and corrosive elements – so purchasing galvanised steel is certainly in your best interests. Additionally, paints with corrosion-resistant properties add an extra layer of protection, enhancing the longevity of the steel.

Proper coating and painting not only prevent corrosion but also improve the aesthetic appeal of the steel products, making them visually appealing in various applications.

Regularly Maintenance And Clean Your Products

Regular maintenance and cleaning of steel products are crucial for preventing the buildup of dirt, debris, and contaminants that can accelerate corrosion. Routine inspections allow early detection of any signs of corrosion, enabling timely intervention and treatment. Cleaning steel products with appropriate solutions and methods removes harmful substances that may trigger corrosion, preserving the product’s structural integrity and appearance. By incorporating regular maintenance into their practices, users can extend the lifespan of steel products and reduce the risk of premature failure.

Consider Cathodic Protection

Cathodic protection is an effective technique used to protect steel from corrosion. By introducing sacrificial anodes or using impressed current systems, corrosion is directed away from the steel and towards the sacrificial material, which corrodes instead. This method is best suited to corrosive environments, such as coastal areas or industrial settings, where steel products are exposed to higher levels of moisture and harsh chemicals. This method of protection is ongoing, reducing the need for frequent replacements and repairs.

Practise Proper Storage And Handling

How steel products are stored and handled can go a long way towards impacting their vulnerability to corrosion. Ensuring that steel items are stored in a dry and controlled environment helps to minimise exposure to moisture and other corrosive agents. Implementing best practices for handling steel products, such as using gloves to prevent the transfer of contaminants, further reduces the risk of corrosion. Proper storage and handling will not only prevent corrosion during transportation and storage but also maintain the quality and usability of the steel products over time.

Control The Environment and Humidity

Controlling the surrounding environment and humidity levels also plays a key role in preventing steel corrosion. In industrial or manufacturing settings, humidity control systems can be installed to maintain a dry atmosphere and prevent excessive moisture from accumulating on steel surfaces. In coastal or marine environments, protective barriers and coatings become even more essential to safeguard against the corrosive effects of saltwater and airborne salts. By controlling the environmental factors that contribute to corrosion, steel products can retain their structural integrity and functionality for prolonged periods.

At Australian Steel Traders, we hold out steel products to high expectations to ensure that you receive the steel products you need to achieve your project’s professional completion. Whether you are sourcing steel for your next project or looking to export steel to Australia, we’re here to make the process as straight-forward as possible. Get in touch today, and let’s discuss your needs.